Thin Walled Tubes

Thin Walled Tubes

Attica Components are experts in the manufacture of precision thin walled tubes. These specialised components can be manufactured from a wide selection of materials, including mild and stainless steels (grades 303, 304 and 316), to form the basis of a wide range of instruments, apparatus and components within medical, aerospace, automotive, robotics and other industries.

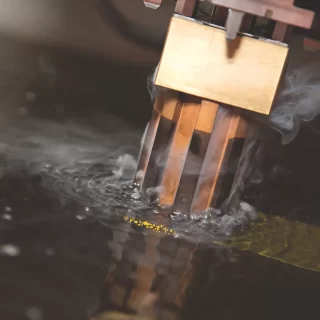

We manufacture thin wall tubes with wall thicknesses from as thin as 50 microns (0.05mm). Through our tube manipulation techniques, including precision laser cutting and welding, CNC sliding head machining and tube bending, swathing and bevelling, we’re able to manufacture thin walled tubes for a range of highly specialised applications. For example, stents for medical use through to flow tubes used in the gas and oil industry.

Ready to work with a world-class engineering partner? Contact Attica Components today.

Thin Wall Stainless Steel Tubes

We manufacture thin wall steel tubes from mild or stainless steel, grades 303, 304 and 316. Steel has unique properties that lend it to a range of applications, including flow tubes to carry specific substances or gases that might react with or corrode other metals.

We can supply lengths of straight thin wall steel tubes, or can use laser cutting techniques to cut the tubing to your specifications. We have a range of tube manipulation processes such as bending, cutting and profiling also available to further enhance thin wall steel tubing to suit specific applications.

Ready to discuss your project or specification? Get in touch with Attica Components.

Other Tubing Materials

Stainless steel tends to be the material of choice when it comes to thin walled tubes. We offer 303, 304 and 316 stainless steel, with 304 being most common commercial grade stainless steel with good corrosion resistance and machinability. 316 stainless steel has superior corrosion resistance and heat resistance and is suited to more critical applications where corrosion resistance is essential, such as marine environments, or heat resistance is required, such as in food processing. We also work with austenitic, ferritic, martensitic, duplex ad precipitation hardened stainless steel.

While the majority of our thin wall tubes are made from stainless steel, we also manufacture tubes from other materials including:

- Nickel & nickel alloys

- Phosphor bronze

- Aluminium (including anodised)

- Precious metals

- Titanium

Have a specialist manufacturing project in mind? Just get in touch with us today to discuss your specifications.

Thin walled Tube Finishes

Depending on the material used we offer a range of finishes to our thin wall tubes.

- Thermal Spray Coatings – coatings to protect components against wear, corrosion, heat and oxidation

- Wet Treatments (Anodising) – offering both wear and corrosion resistance

- Electroplating – improving durability, surface friction, corrosion resistance and aesthetic appearance

- Polishing/Buffing/Honing/Lapping – reducing surface roughness which can be measured on the micron level and finished to the customers specifications

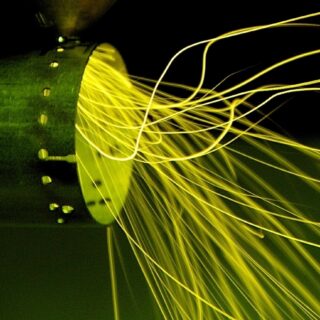

- Grinding – using grinding wheels to smooth the surfaces of the component

- Vibratory Finishing – deburring, descaling, polishing, burnishing & removing sharp edges, sprue etc,

- Heat Treating – removing any residual stresses developed during the manufacturing process and hardening the metal

- Hot Blackening – adds a matte black finish with high abrasion resistance

- Anodising – adds a protective layer to improve corrosion resistance and prolong its appearance

Examples of Micro Tubes

Precision thin wall tubes are used in a variety of drug delivery and sensor applications, as well as in process industries, the oil and gas industry, high-specification printer applications and heat exchangers. Wherever delivery of a liquid or gas into a confined space is required, a thin wall tube made from strong material is often used.

Flow Tubes

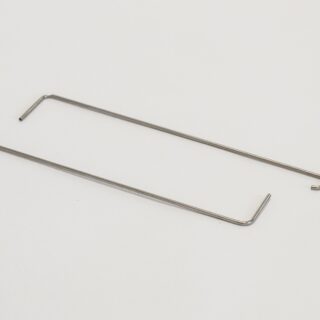

Flow tubes transport substances or gases in a pressurised, or sometimes high temperature, environment. To manufacture flow tubes, an assembly is required of three thin wall stainless steel tubes placed in parallel. The tubes are lightly tack-welded by laser to keep them in the correct configuration relative to each other to function effectively.

Optoelectronic Components

These optoelectronic components require both a nickel-iron-cobalt (kovar alloy) tube and a stainless steel tube. The two must be of relatively thin wall thickness and the kovar alloy tube is placed inside the stainless steel tube. We then use laser welding to join the tube.

Kovar is used in this application due to its unique properties. It’s effective as a glass to metal, or ceramic to metal, seal and has low thermal expansion, similar to high-borosilicate glass. This means it is frequently used for glass-metal seals in x-ray tubes or glass lasers. It is sometimes desirable for a sealing assembly to be manufactured from kovar plus some other alloy, such as stainless steel, as is the case here. This gives added strength and allows the component to handle different applications. Similarly, nickel-iron alloys are used as radio frequency shields, but can be welded to stainless steel components by laser welding.

Get In Touch

35 Ganton Way

Swindon

SN2 8ES