Services

Your Requirements

For new products and products undergoing design changes, we plan an initial meeting with clients to gain a detailed understanding of the project brief and functional requirements of the end product.

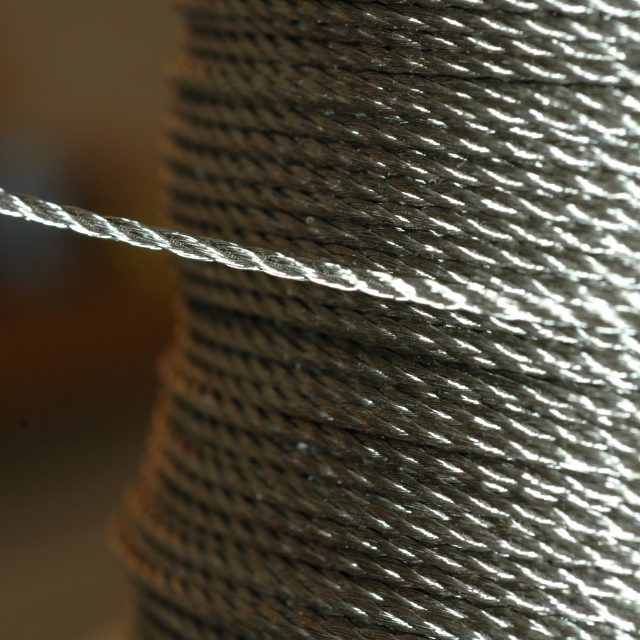

Working closely together, we realize solutions for our clients, utilising the broad variety of materials and processes available to us. We endeavour to provide medical devices, welded and seamless tubes and a host of other assemblies that are functional, yet economical.

Our in-house manufacturing services include CNC miniature part machining, specialist metal forming, micro welding and vacuum brazing techniques.

Being involved in the initial planning stages of a project means that our clients receive a seamless experience with our team, transcending design through to prototype to pilot and full-scale manufacturing.

An experienced and highly skilled workforce, combined with years of manufacturing proficiency allows us to offer a service tailored to our client’s requirements, delivering optimal solutions. Get in touch with us today to find out more.

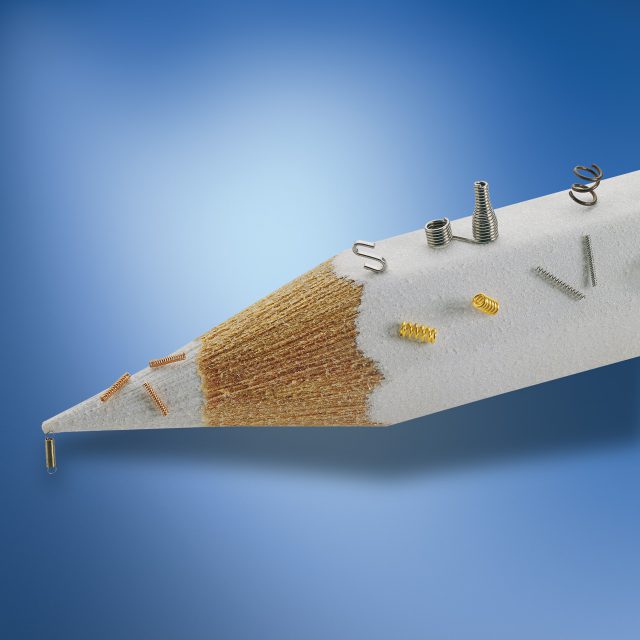

Typical Projects

Working across six sectors and proudly based in the heart of the UK, Attica has successfully delivered on a multitude of projects since inception. Varying from manufacture and assembly to procurement, our specialist team work to exacting standards, providing competent, high-quality solutions time and time again. Find out more about a selection of the projects we’ve worked on by clicking the links below.

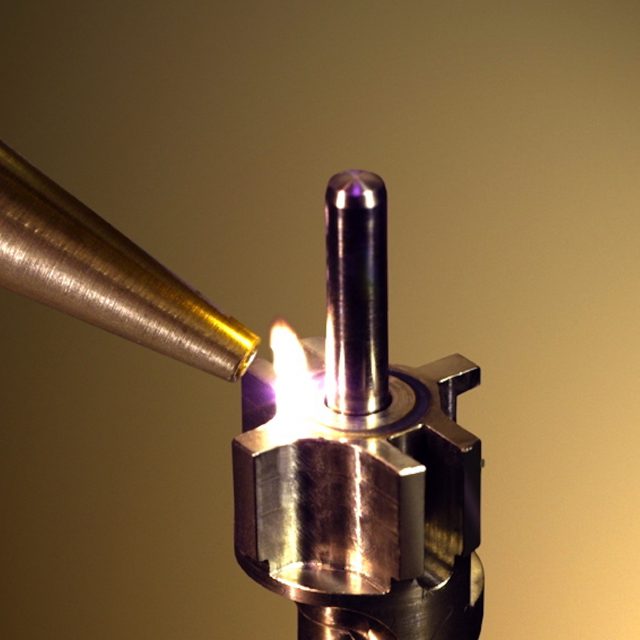

Welded Sensor

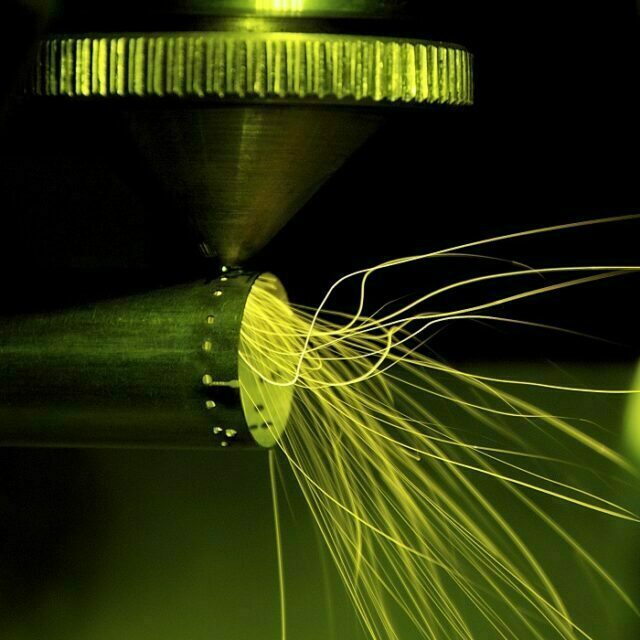

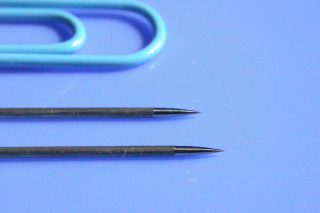

Tungsten Tips

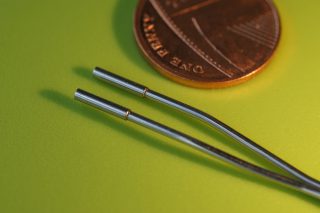

Temperature Probes

Stent

Pressure Probe

Intubating Laryngeal

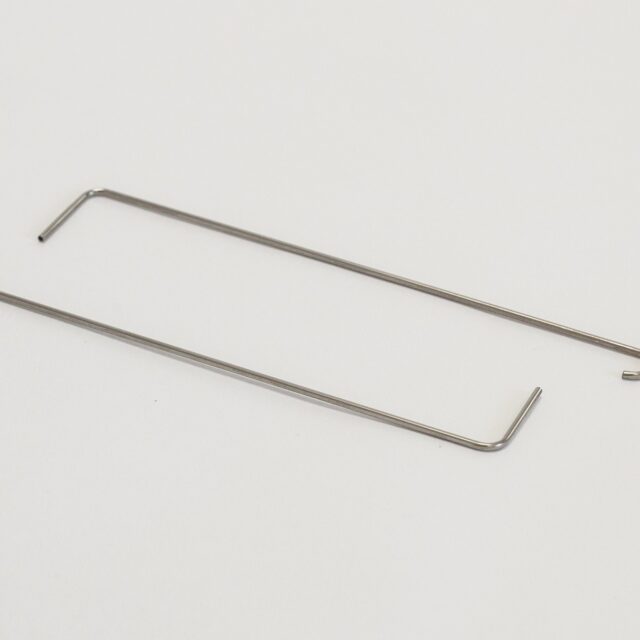

Formed Wire Spring

Miniature Probe

Wedge Tips

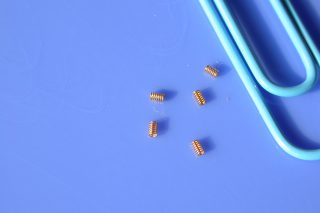

Miniature Coils

Flesh Ablateon

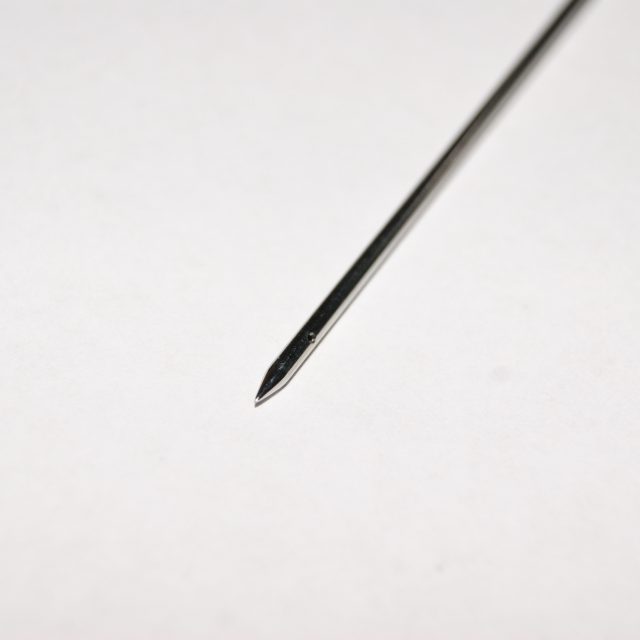

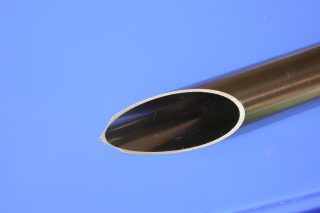

Bevel Ended Needle

Flash Abateon

Active Rings

Dongnut Jammer

Flesh Abateon Wire

Our Strengths

The sectors we work in are demanding. Standards have to be high, and excellence has to be achieved. We believe that only the very best will do. Working by this value has earned our reputation for quality and a name synonymous with trustworthy performance.

Experience

Quality

Dependable

Competitive

Inspections

Get In Touch

35 Ganton Way

Swindon

SN2 8ES