Sliding Head Machining

Sliding Head Machining

If you’re looking for incredible performance for small, high-volume precision components, then sliding head machining is a great choice to manufacture your machined parts. Our CNC sliding head lathes provide extreme accuracy and versatility due to their extremely effective layout and tooling options.

Working with us gives access to a team of specialists with years of manufacturing experience, who will assist you with your project. Our aim is to attend to your requirements to the highest detail and deliver excellent results. Get in touch with us today to find out more.

What are Sliding Head Lathes?

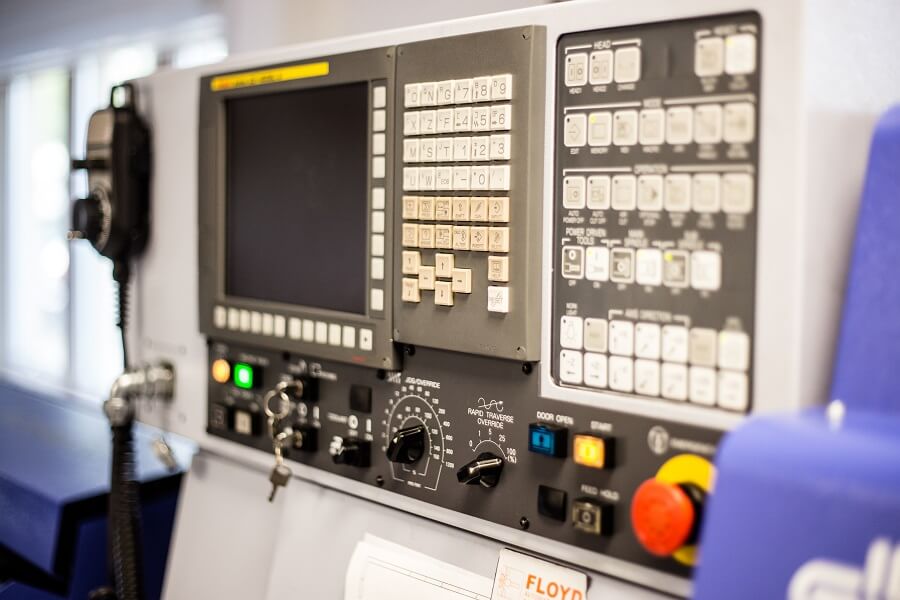

CNC sliding head lathes, commonly known as Swiss-style lathes, are modern machine tools controlled by computer numerical programming, which perform machining operations with extreme accuracy.

Our sliding head lathe machines are computer numerical controlled (CNC), which means that they carry out fully modern processes with improved machining accuracy and greater flexibility in manufacturing. This also enables complex detailed tasks to be completed, which is the reason why this specialised technology is used across a broad range of industries, such as:

- Aerospace

- Automotive

- Electrical connectors

- Electronics

- Sensors and Instruments

- Measuring equipment

- Fasteners

- Marine

- Medical

- F1 & Motorsport

- Cryogenics

- Oil and Gas

- Nuclear

- Aeronautical

- Off Earth Manufacturing

- Defence

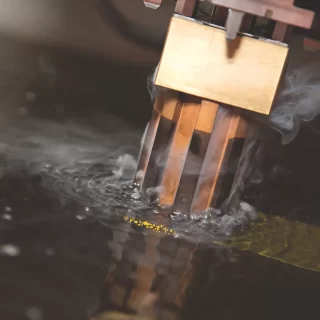

How does a Swiss-style lathe work?

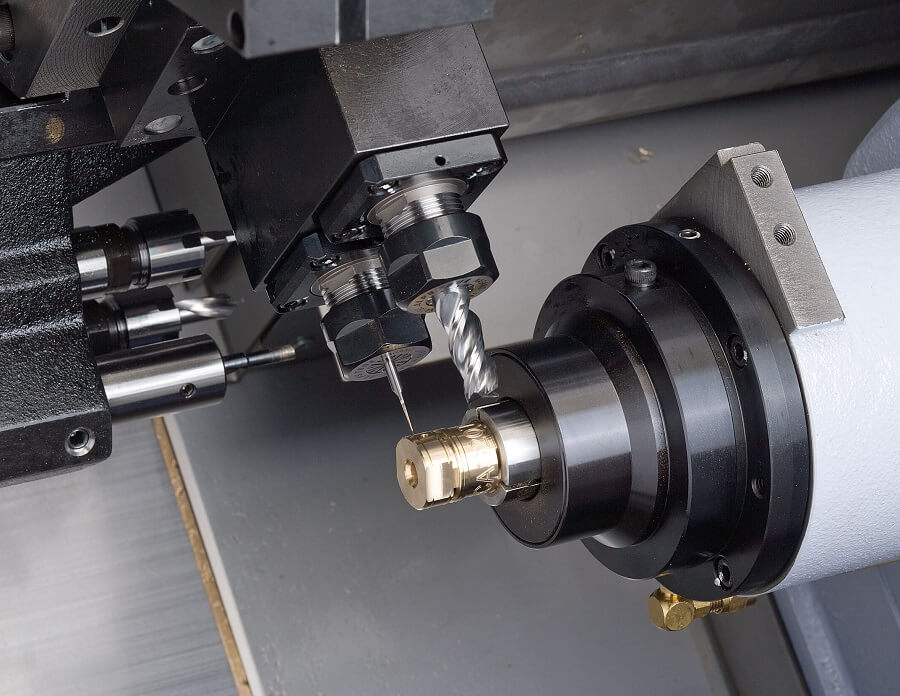

Swiss-style lathes hold the workpiece with both a collet and a guide bushing. The tools are positioned in front of the guide bushing and the collet sits behind it. Unlike traditional lathes where the part is stationary and the tool moves, CNC sliding head lathes allow the part to move in the Z-axis, while the tool is stationary. This provides much greater precision.

The workpiece slides through the guide bushing and is rotated by a second spindle. The second spindle also pushes the workpiece through the guide bushing. As the tools and the lathe’s Z-axis stay close to the guide bushing, the movement of the workpiece is more efficient, resulting in maximum stability and accuracy.

The use of a second spindle, together with CNC control, eliminates the need to have an operator manually change each part between different operations, which makes Swiss-style lathes notably effective.

Benefits of Sliding Head Machining

Also known as sliding head turning, this modern technology offers many advantages and capabilities to your projects. Contact Attica Components today.

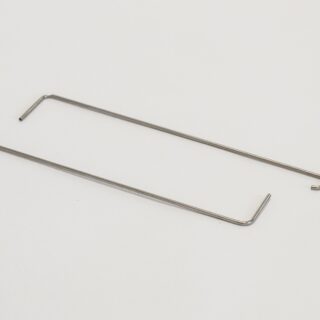

Precision

Even though narrow parts relative to their width are subject to deflection in most machining processes, CNC sliding head lathes challenge provide precise results and manufacture parts up to a 20:1 length to width ratio.

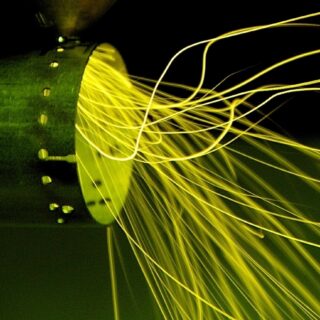

Efficiency

Swiss-style lathes are extremely efficient. These machines are capable of fast cycle times, producing simple parts in one cycle. The sliding head machines’ secondary spindle is able to accept the part for second operations, eliminating the need to have an operator manually change each part. It makes your production more efficient.

Versatility

CNC sliding head machining offers greater diversity and versatility in the type of machining that can be done in just one process. A CNC sliding head lathe is capable of turning, milling, and threading to drop complex parts complete. Furthermore, technological advancements in Swiss-type lathe programming allow us to handle more complex machined components out of a variety of materials, including:

- Steel

- Stainless steel

- Aluminium

- Brass

- Titanium

- Inconel

- Copper

- PEEK

- High Temperature Alloys

- Brass Alloys

- Bronze Alloys

Contact Us Today

Get In Touch

35 Ganton Way

Swindon

SN2 8ES