Laser Cutting

Precision Laser Cutting

Attica Components use the latest technology to provide some of the most precise laser cutting services in the industry. We are specialists in manufacturing miniature precision components and can cut holes just 0.02mm in diameter.

Our precision laser cutting services can manufacture components with holes, slots, intricately cut designs or shaped ends. It allows us to manufacture components for a range of industries including medical, automotive, aerospace, robotics, electronics and many more. Get in touch with us today to find out more.

Materials

- Stainless steel 303, 304 and 316

- Mild Steels

- Aluminium

- Inconel

- Nitinol (nickel-titanium alloy)

- Titanium

Laser Cutting Technology

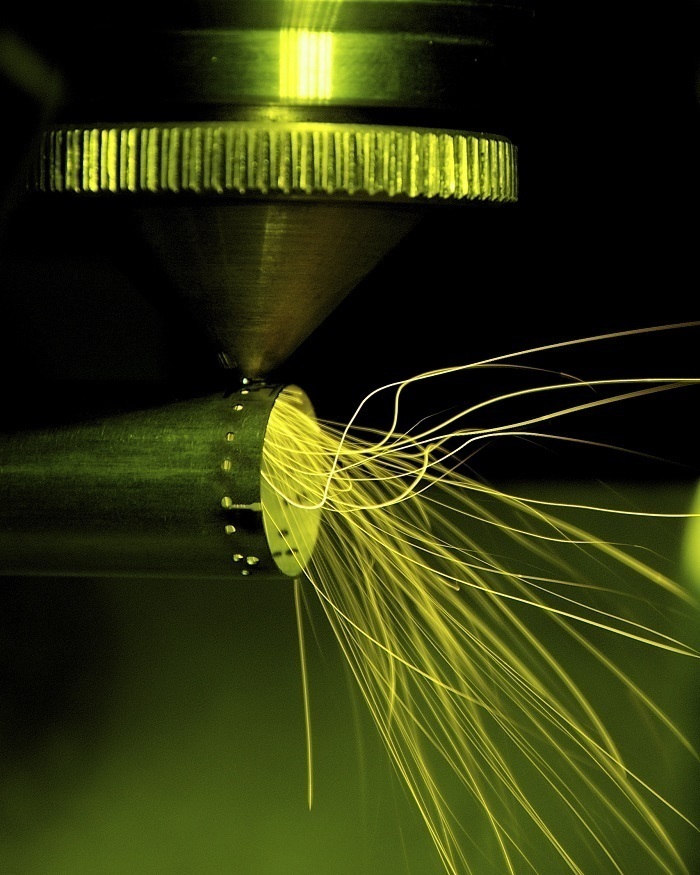

Precision laser cutting requires a highly accurate laser beam. We use picosecond fibre lasers and our Nd-YAG fibre laser to focus a beam of just 0.02mm in diameter onto the metal component.

The parallel coherent light vaporises the metal in an extremely precise area. By moving the component along both the X and Y axes, we can form highly intricate designs in the material according to your specifications. This could include holes, slots or complete shapes and forms.

This method of precision laser cutting can be used to create stents or miniature needles for medical applications, laser cut tubes, active rings, inconel seals, electronic components and hundreds of other components.

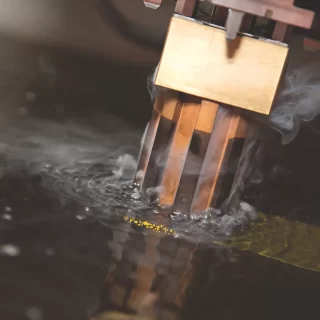

Alternative Cutting Services

Attica also has alternative cutting methods including EDM, or electro-discharge machining. Simply get in touch and we can advise on the best process for your component manufacture.

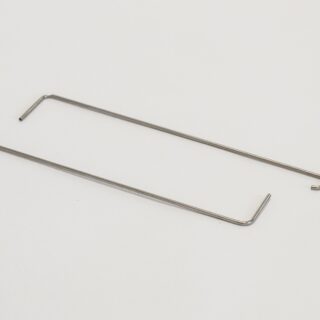

Examples of Laser Cut Components

Inconel Seal & Cold-Ablation

Inconel can be a difficult metal to machine mechanically, but using a picosecond fibre laser allows us to create an extremely precise cut and leave a smooth surface that’s ideal for sealing.

To create an inconel seal, a 1.8mm hole is drilled mechanically through the inconel plate. A seal is then needed between a ceramic cone shape piece and the entry to the hole in order to prevent liquid incursion under high pressure. A hole is made to solve this problem at a precise angle to match that of the ceramic cone.

A picosecond fibre laser creates a highly focussed beam, which cuts through the Inconel, leaving a smooth surface requiring no further processing.

This “cold-ablation” process is useful for drilling small holes and micro-machining, as well as scribing and cutting a wide variety of materials and metals such as molybdenum, platinum, nickel, titanium and nitinol. Applications include semiconductor and bio microfluidic devices.

Stents

Stents are one example of precision laser cutting applied to a tube. A nitinol tube must be able to extend and retract in order to be useful in stent operations in medical settings; a nitinol stent may be designed to be delivered through a 2-mm sheath and expand to support a 10mm diameter blood vessel. Laser cutting allows removal of a portion of the nitinol tube to allow it to flex into a smaller diameter, or to expand itself to a larger diameter.

We focus a high power laser beam just below the surface of the nitinol tube and use an assist gas which helps with both the cutting itself and the removal of molten metal. In this application of precision laser cutting, widths are typically 10-15 micrometers to create an intricate pattern.

Find out more about laser tube cutting and its applications.

Why Choose Attica Components?

Within component manufacture, multiple processes are often required and Attica offers them all. We can combine precision laser cutting with welding or CNC machining to complete components to your specifications.

We can run full production assemblies or prototype manufacture, and have decades of experience behind us. Simply get in touch today.

Contact us to find out how we can help

Get In Touch

35 Ganton Way

Swindon

SN2 8ES