Tube Manipulation

Tube Manipulation & Forming

Attica Components are experts in all varieties of miniature component manufacture, including tube manipulation and precision tube forming. This includes laser tube cutting, cutting patterns or designs into material, welding and small diameter tube bending. Precision tube forming and manipulation is used to make components used in the medical, scientific instrumentation and aerospace industries, among many others.

Specialists in Component Manufacture

Attica has developed tooling to swage, flare, bend and cut tubes to our customers’ precise designs. Requirements for exotic alloys and special metals in critical applications have led us to supply coiled springs, tube in coils, swaged and formed tubes and wires made to close tolerances.

Tube Manipulation Techniques

We have a full range of capabilities available to manufacture tube components including welding, cutting and bending.

We have a range of different cutting techniques used in tube manipulation.

Abrasive cutting is used to provide a sharp, clean cut to create precision tubes and rods. A spinning tungsten carbide impregnated, or diamond grit impregnated, wheel is used to slice through metals from tungsten to stainless steel, producing a polished finish and an accurate cut at the end of the tube or rod.

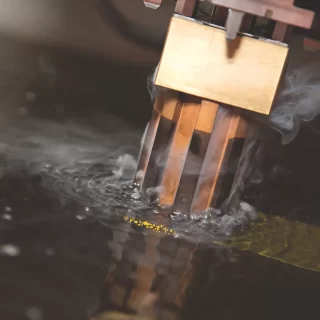

EDM wire cutting can also be used. It provides a more accurate cut than abrasive, although the latter is still commonly used where a fast cutting speed through a large cross section of metal is important.

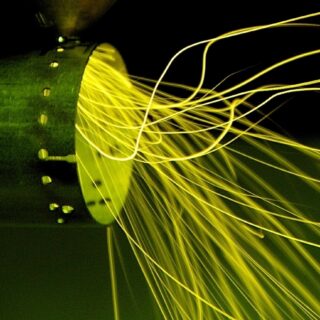

We also have the latest precision laser cutting technology available. This involves using a highly accurate laser beam to vaporise the metal tube in a precise spot. By moving the component on the X and Y axes, intricate patterns, designs, slots and cuts can be made in the material.

Small Diameter Tube Bending

Tube bending and other tube manipulation processes are carried out by Attica in tube diameters between 1mm to 16mm.

Shaped tubes, including rectangular profiled tube, oval and flat-oval shaped tube and other shapes are one of our specialties. While thin-wall tubes can often be difficult to bend or swage, we deliver small diameter tube bending with wall thicknesses as low as 0.05mm and diameters up to 30mm.

Materials

Materials include both metals and alloys:

- Aluminium

- Hastelloy

- Inconel

- Mild steels

- Molybdenum

- Monel

- Nickel

- Nitinol

- Rhenium

- Stainless steel

- Tungsten

- Precious metals

Examples of Tube Manipulation Components

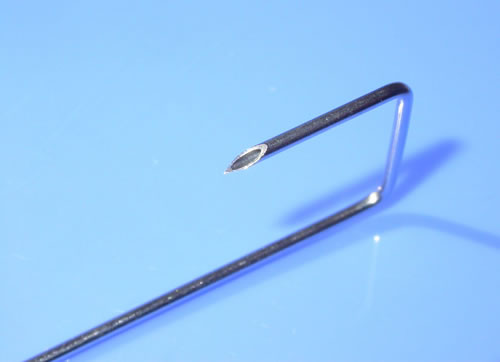

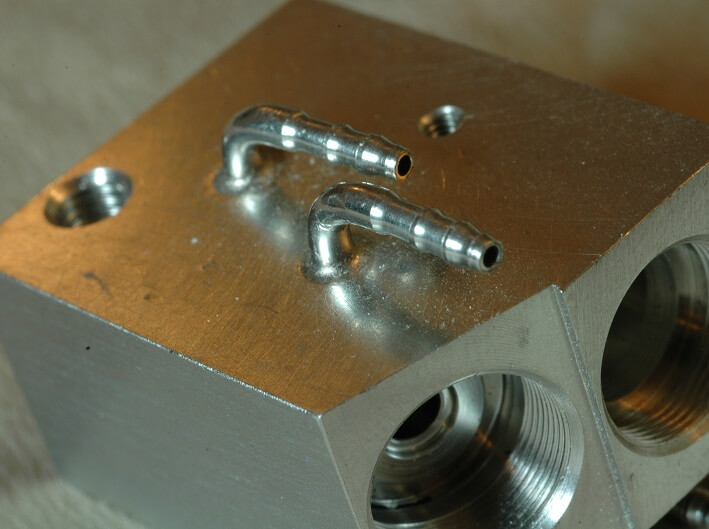

Barbs

Attica makes special tooling to bend the barbed tubular part of the barb, which has an outside diameter of 2mm. Through tube bending, it is angled at 90 degrees without damaging the component. The part is inserted into a machined stainless steel block, and vacuum brazed into place.

Vacuum furnace brazing is often used for joining precision components in corrosion and heat resisting materials. It produces high integrity joints in stainless steels and nickel-based alloys using predominantly nickel based filler materials. However, laser welding is often the preferred method of joining as it usually reduces the need for filler material and can be used on a wide variety of metal materials, including stainless steels and nickel alloys.

Brazing is carried out in a vacuum of around 10-4 mbar without flux. Assemblies come out of the furnace clean and without discoloration or distortion. Similarly, when laser welding is used, the joint area is shielded with argon to reduce oxidation; the final component is not affected by discolouration and has an extremely strong joint.

A combination of tube manipulation and bending techniques, alongside brazing or laser welding, is required to manufacture these barbs.

Opto Electronics

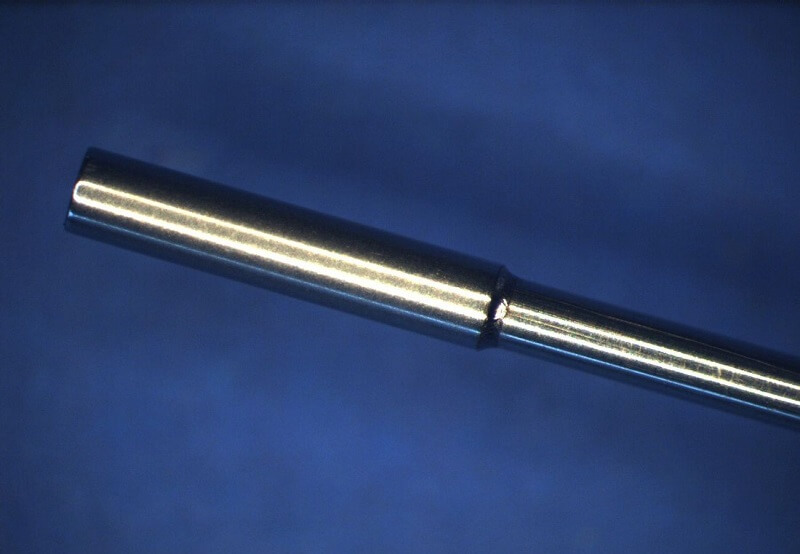

A miniature nickel-iron-cobalt (kovar alloy) tube is placed inside a stainless steel tube and the two are laser welded around the tube joint.

Kovar has low thermal expansion similar to high-borosilicate glass and is frequently used for glass-metal seals, especially for the application in x-ray tubes or glass lasers. It is sometimes desirable for a sealing assembly to be manufactured from Kovar plus some other alloy, such as stainless steel. Similarly, nickel-iron alloys are used as radiofrequency shields, but can be welded to stainless steel components by laser welding.

In this example, laser welding is used in the tube manipulation process to produce the final component.

Profiled Tube Assembly

We laser cut holes into a brass rectangular tube, which is profiled with an internal channel running along one side. The tube acts as a radio-frequency shield for electronic circuitry, which is placed inside. Plates are first laser tack-welded to the tube ends then joints are soldered to secure the ends and to maintain an RF seal.

We have the facility to manipulate, weld and cut brass, phosphor bronze, nickel silver and other copper alloy tubes.

Get In Touch

35 Ganton Way

Swindon

SN2 8ES