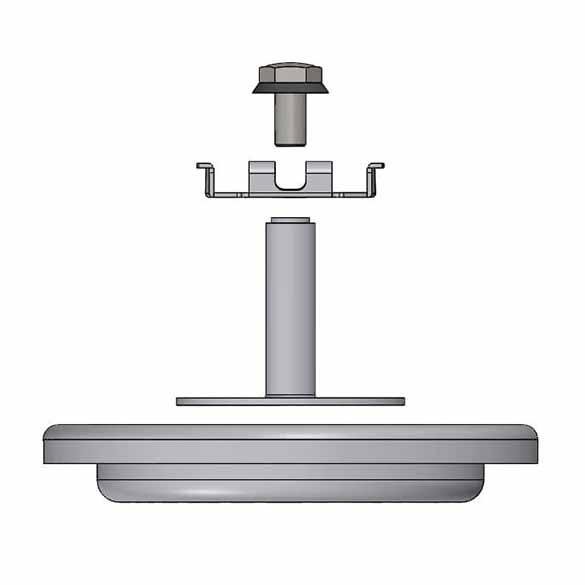

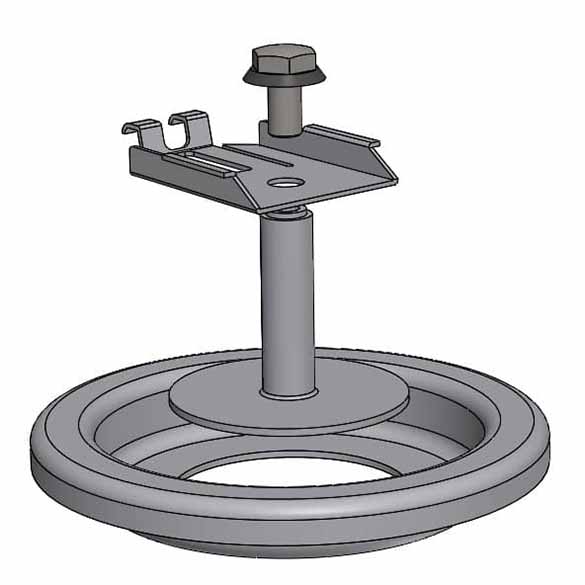

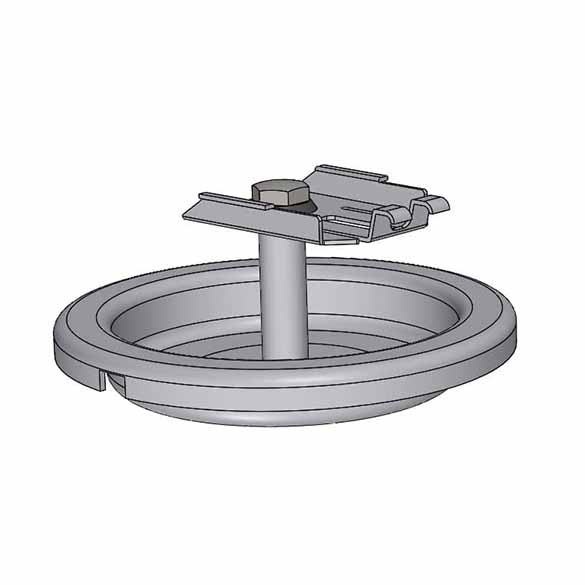

Bespoke Assemblies

Bespoke Miniature Assemblies

Attica is a leading specialist manufacturer & supplier of miniature precision components based in Swindon, Wiltshire and our primary mission is to manufacture bespoke components to our unwavering high standards while providing excellent customer service.

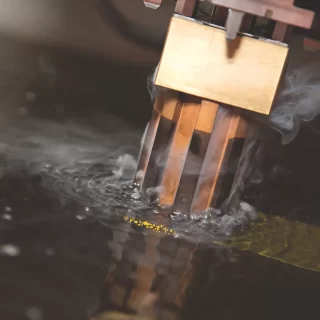

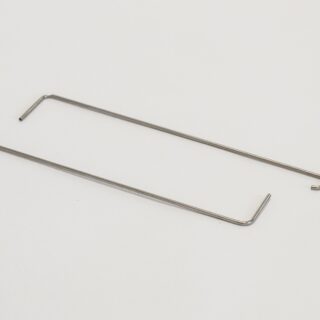

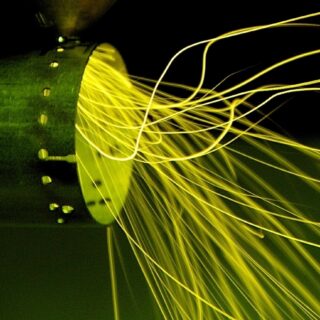

We have the expertise and capabilities to employ a wide range of techniques to manufacture precision miniature parts to the exact specifications of our customers, from laser welding (including laser spot welding, seam welding and micro-welding) and CNC turning (Swiss-style and fixed head), to tube forming, bending and manipulation. Get in touch with us today to find out more.

Quality micro precision components

We employ industry standard CAD software to specify every detail of a component, dimensions are specified to within X microns, dependant on the material and overall dimensions of the component.

We use rigorous quality assurance procedures, including visual inspection and CMM (coordinate measurement machinery) analysis. Our DEA Global Classic 500×500 CMM employs touch trigger probes and/or optical scanning probes to inspect the dimensions and fixture qualification of completed components to ensure each component is manufactured to specification within allowed tolerances.

Our high standards and quality system are regularly audited and assured to ISO 9001 standards and we internally review our own strict testing procedures which include vigorous inspection and traceability as standard. We are committed to delivering on time and within budget to exceed our customers expectations and continually work towards enhancing our processes.

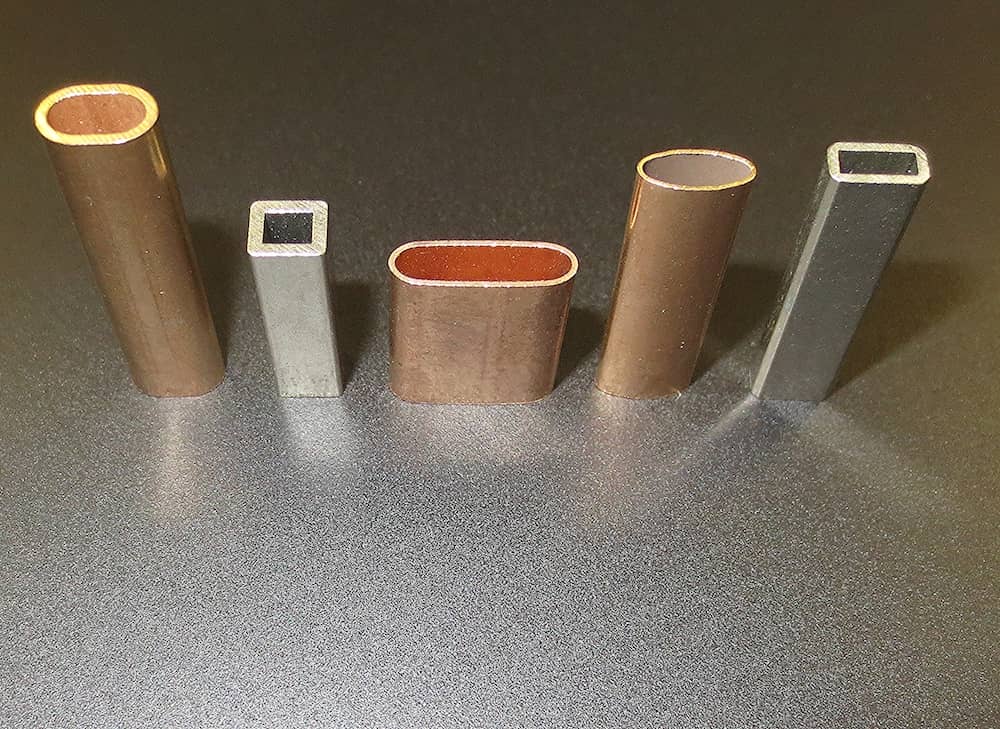

Materials

As specialist miniature component manufacturers we can work with a wide range of materials to meet our customers requirements, including but not limited to stainless steel (e.g. 17-4 PH, 316), nickel alloys (e.g. Kovar, Monel or Hastelloy), brass & copper alloys, titanium, platinum and other precious metals, compound materials such as tungsten carbide as well as non-metals such as ceramic and PEEK (polyetheretherketone).

Metal finishes

In addition to our bespoke miniature parts manufacturing services we also offer a range of finishes to ensure reliable component performance and/or a pleasing aesthetic finish depending on our customers requirements.

The metal finishes we offer include:

• Thermal Spray Coatings – coatings to protect components against wear, corrosion, heat and oxidation

• Wet Treatments (Anodising) – offering both wear and corrosion resistance

• Electroplating – improving durability, surface friction, corrosion resistance and aesthetic appearance

• Polishing/Buffing/Honing/Lapping – reducing surface roughness which can be measured on the micron level and finished to the customers specifications

• Grinding – using grinding wheels to smooth the surfaces of the component

• Vibratory Finishing – deburring, descaling, polishing, burnishing & removing sharp edges, sprue etc,

• Heat Treating – removing any residual stresses developed during the manufacturing process and hardening the metal

• Hot Blackening – adds a matte black finish with high abrasion resistance

Supply chain management

We also offer supply chain management to ensure we can deliver to your requirements consistently and reliably, no matter what time period you require our services for. For more information about how we can help with your supply chain management please get in touch.

Contact us to find out how we can help

Get In Touch

35 Ganton Way

Swindon

SN2 8ES