Micro Tubes & Needles

Precision Miniature Tubes & Needles

Attica Components are miniature precision engineering experts with decades of experience in the manufacture of highly precise metal components. We manufacture high quality, precise hypodermic needles, biopsy needles and other speciality miniature tube products, such as complex tubular components, sub-assemblies and precision thin walled tubes [LINK], by tube bending, tube machining, tube laser cutting, laser ablation and other tube forming techniques.

We work across a variety of sectors (such as medical, oil and gas, automotive, aerospace and industrial to name a few) and have the capabilities to manufacture micro tubes to a wide range of specifications.

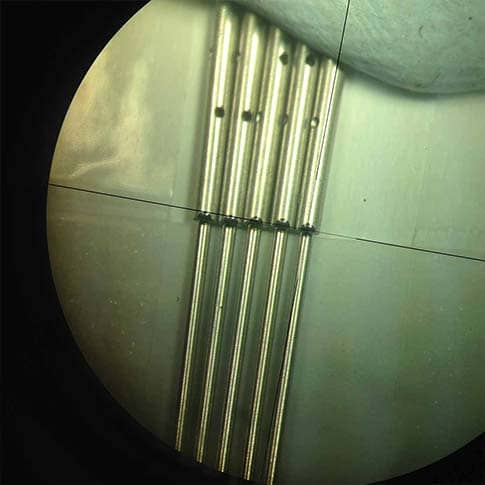

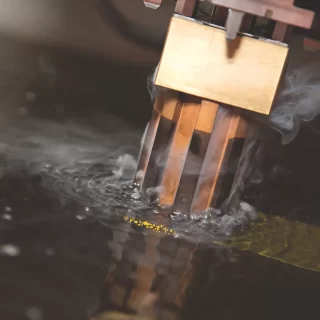

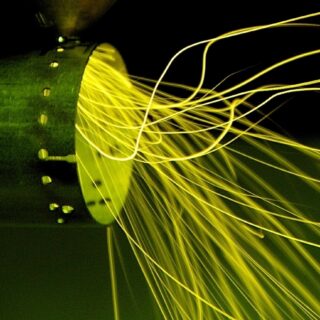

Laser cutting is used to produce a highly consistent, burr-free cut, either in the wall of miniature tube, or to cut the end in a particular shape. We can laser-cut tubes between 0.3mm and 30mm diameter.

Customer service is at the heart of our business and this feeds our drive towards producing the highest quality components, efficiently and with stringent quality assurance processes. We are assured to ISO 9001 standards and regularly review our own processes to ensure the consistent high standards our customers have come to expect are met every time.

Get in touch with us today to find out more.

Micro tube forming methods

Miniature tubes and micro-tubes can be swaged, reducing the diameter along part of their length, creating a funnel-effect in the tube.

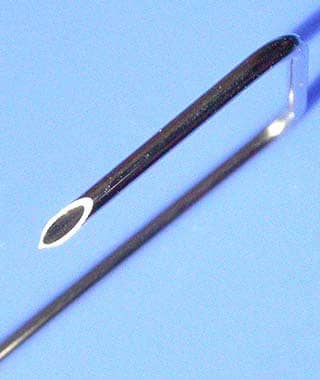

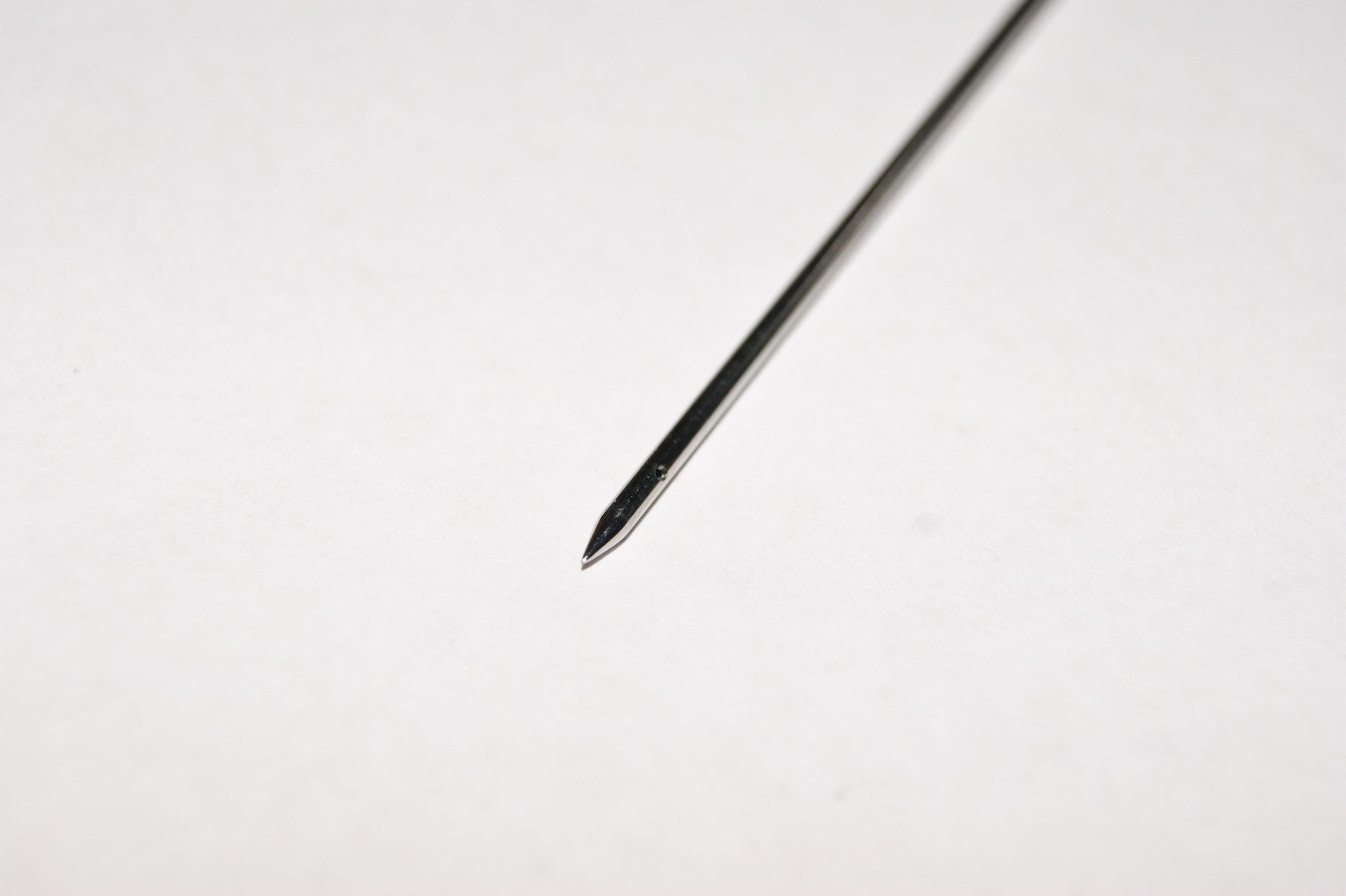

Flared tubes are made by “push-pointing”, forcing a mandrel into the end of a tube to increase its diameter, at the same time making its wall thinner at one end. Grinding the end of a tube produces a bevel end, which gives a sharp point for introducing a needle through soft tissue or skin.

We can perform a variety of laser cut patterns into micro tubes to meet our customers requirements in flexibility and performance, from continuous/interrupted spiral and radial patterns, to bespoke patterns and hole cutting.

Speciality needle manufacturer

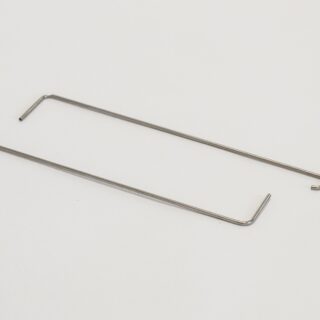

Speciality needles can be made by a combination of grinding a bevel point, micro-joining to a luer or hub, by laser welding or crimping, and bending or forming the needle to suit the application. Biopsy needles are used to extract tissue. We work with medical device companies to ensure that biopsy needles and drug delivery systems are effective in their function. Most medical devices require the use of stainless steel, but other exotic metals and alloys including titanium and platinum are also available as miniature tubes.

Stents are cut from stainless steel tube and nitinol tube for a wide variety of medical applications.

Micro tube materials

While the majority of our thin wall tubes are made from stainless steel, we also manufacture tubes from other materials including:

• Stainless Steels

• Nickel & nickel alloys (e.g. Kovar, Monel or Hastelloy)

• Phosphor bronze

• Precious metals

• Titanium

Have a specialist manufacturing project in mind? Just get in touch with us today to discuss your specifications.

Contact us to find out how we can help

Get In Touch

35 Ganton Way

Swindon

SN2 8ES